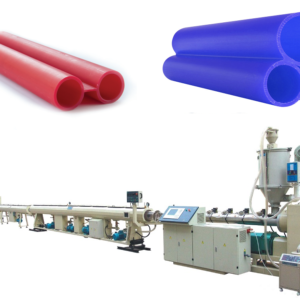

PPR Pipe Extrusion Line

Raw material—–mixing—-vacuum feeder and drier—–single screw extruder—–co-extruder—–mould and calibrator—–vacuum forming table—–water tank (spraying cooling tank) —— haul-off machine —— cutting machine—– stacker(winding machine).

Description

The feature of Plastic PPR Pipe and machinery:

1) PPR pipes are used widely for hot&cold water, central heating system and so on.

2) The production line can choose to load labeled extruder to produce pipe material with color labeled.

3) It can also produce PE pipe.

The working process of Plastic PPR Pipe machinery:

Raw material—–mixing—-vacuum feeder and drier—–single screw extruder—–co-extruder—–mould and calibrator—–vacuum forming table—–water tank (spraying cooling tank) —— haul-off machine —— cutting machine—– stacker(winding machine).

Main Parameters of PPR pipe extrusion line

| Model | PipeSize(mm) | Extruder Model | Speed Screw (r/min) | Line Speed (m/min) | Output (kg/h) | Total Power (kw) |

| PPR-63 | Ø20-63 | SJ-75/30 | 40-120 | 4-15 | 100 | 70 |

| PPR-110 | Ø20-110 | SJ-90/30 | 40-120 | 4-10 | 200 | 100 |

| PPR-160 | Ø75-160 | SJ-90/33 | 40-120 | 2-8 | 300 | 136 |

Reviews

There are no reviews yet.